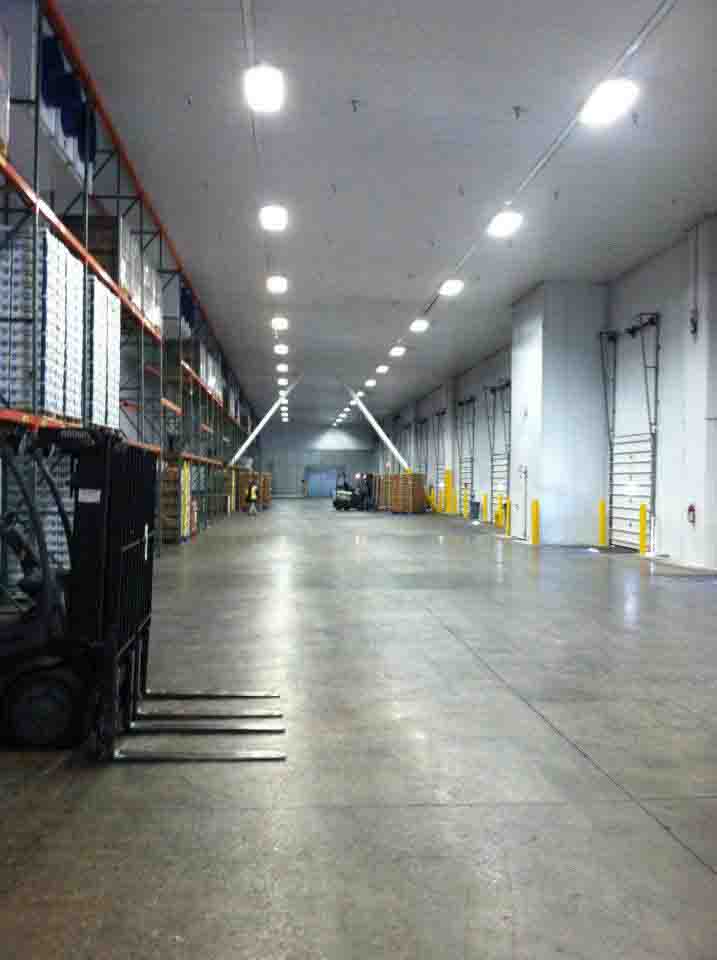

Inside the Santa Barbara Chocolate Cold Storage Warehouse

A strong dedication to quality, careful handling, and exact storage are all parts of the process that go into making each rich bite of chocolate. At Santa Barbara Chocolate that journey continues long after production. The way chocolate is stored can directly affect taste, texture, and shelf life. That’s why all products are housed at a dedicated cold storage facility in California, inspected and approved by the FDA, USDA, and Kosher authorities.

Maintaining a consistent environment helps ensure each bar, chip, or couverture product reaches its destination as fresh as it was when it left production. While the spotlight often shines on chocolate-making, the storage process is equally important. This behind-the-scenes step protects chocolate from common issues such as bloom, melting, and flavor loss.

Large warehouse racks where pallets of chocolate are stored.

The Purpose of Cold Storage for Chocolate

Chocolate is highly sensitive to temperature and humidity. It prefers stable, cool environments that shield it from fluctuations that can damage its structure. Cold storage isn’t just about keeping products cold — it’s about creating ideal conditions. For this reason, chocolate should be kept in a room with a temperature that is set between 55°F and 65°F and a low humidity level to avoid condensation.

Without this kind of protection, chocolate is more likely to have problems with visual and texture. One example is fat bloom — a whitish coating that appears when cocoa butter separates due to temperature swings. While safe to eat, bloom can make chocolate look unappealing. A professionally managed facility eliminates these risks allowing chocolate to retain its signature snap, aroma, and shine.

A Look at the Santa Barbara Chocolate Facility

The cold storage warehouse is a large-scale, organized space filled with high-rack shelving and precisely stacked pallets of chocolate products. It’s not just about capacity — it's about consistency, cleanliness, and efficiency. With inspections and certifications from the FDA and USDA, the facility upholds high food safety standards.

Kosher certification is also part of the operation, ensuring that products meet dietary standards valued by many customers. These standards are more than labels, they reflect a culture of accountability and transparency.

Each section of the warehouse is designed with purpose — from intake and inspection areas to shipping docks and long-term storage zones. Chocolates are checked before they are put away after coming from known suppliers all over the world. After that, orders are packed, and sent to bulk or retail customers in a way that keeps them safe from temperature changes.

The Team Behind the Chocolate

While equipment and climate control matter, the people managing the process are equally essential. Warehouse managers and staff at Santa Barbara Chocolate bring care, and attention to every step of the storage cycle. Monitoring conditions, handling product rotation, managing inventory, and making sure shipments are ready properly are all part of their job.

One of the most human aspects of this technical environment is the genuine love for chocolate shared among the team. On any given afternoon, it’s not uncommon to see warehouse managers enjoying a well-earned chocolate break — a small reminder of why the process matters.

Chocolate Storage That Preserves Quality

Proper chocolate storage helps protect the product through all stages of its journey from production line to delivery. All of these things—cocoa powder, couverture blocks, and chocolate chips are aware of their surroundings. That’s why the facility remains under strict temperature control 24/7, ensuring chocolate doesn’t suffer from heat exposure or moisture-related issues.

This controlled environment supports the quality expectations customers have when ordering from Santa Barbara Chocolate. Whether a chef is using the chocolate in a high-end dessert or a health-conscious consumer is baking with cacao, the product arrives ready to perform.

Why Proper Handling Matters in Wholesale Chocolate?

Customers who buy in bulk rely on consistent product quality. This is especially true for those who bake, sell, or make things with Santa Barbara Chocolate's ingredients. Poor storage at any stage could compromise the flavor or stability of large batches of chocolate. That's why companies that deal with large amounts depend on cold storage, and shipping that doesn't affect the weather to protect their investment.

The cold storage warehouse is part of a larger system of quality assurance. It reflects Santa Barbara Chocolate’s commitment to delivering reliable products, regardless of scale. The way that the chocolate is handled is the same whether a customer orders a 2-pound bag of cacao powder or several boxes of couverture.

Behind the Scenes of Chocolate You Can Count On

Every product sent from the cold storage facility is a result of coordination between supply chain management, food safety practices and a commitment to freshness. From intake at the shipping dock to the carefully stacked pallets inside the warehouse, every step supports product integrity.

The people working behind the scenes — the ones receiving shipments, checking inventory and packing orders are all part of what makes Santa Barbara Chocolate dependable. Their attention to detail supports the flavor and quality that the brand has come to represent.

There's a whole business behind that smooth bar of dark chocolate, or that bag of organic cacao powder that customers may only see when they open the package. While the chocolate speaks for itself, the environment that preserves its quality makes all the difference.

To learn more about our chocolate making: https://www.