The Journey from Cocoa fruit to Chocolate

Image source: https://www.santabarbarachocolate.com/100-cacao-organic-unsweetened-chocolate-chips-criollo-mini-wafers/

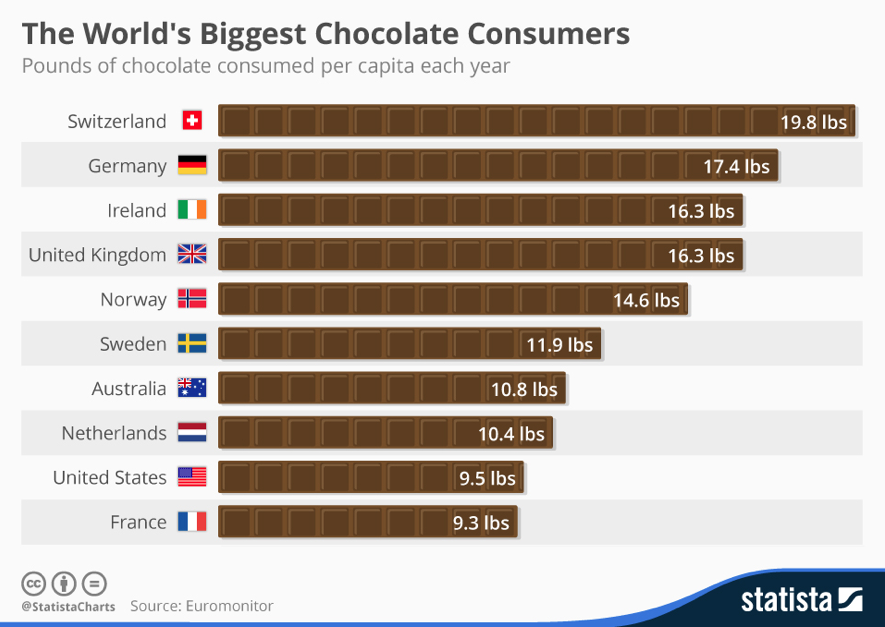

Chocolate, a delectable symbol of luxury and indulgence, has a an interesting history [1]. For over 3000 years, chocolate, like gold, was a highly prized passion. From the jungles of Amazon to Europe, it was brought by Spanish explorers who went there to find gold and instead brought chocolate back to Europe. Its value was quickly realized and chocolate was considered as the food fit for royals exclusively until the 19th century. When the mass production of chocolate took hold in Europe, the demand for it spread far and wide in no time. Nowadays, billions of pounds of chocolate are consumed every year by people all around the world. As per the survey conducted by Satista [2], these countries are ranked in the top ten in chocolate consumption every year:

Have you ever wondered how chocolates are actually made?

Go ahead and read on to see how raw cocoa beans are processed into a scrumptious bar of chocolate.

The making of chocolate is a fascinating combination of science, precision, and art. It's actually quite complex and factors such as ingredients, temperature, and time play a vital role in producing unique varieties of chocolates. It starts with cocoa farms where cocoa beans are produced.

Cocoa Beans Origin

Image source: http://www.indiatimes.com/health/buzz/health-benefits-of-cocoa-beans-242096.html

Cocoa [3] - an essential ingredient for chocolates is grown on trees just like other types of fruit. These trees only grow in the tropical heat which makes countries around the equator in Africa, Asia and Latin America ideal for mass production of cocoa. Cocoa pods are harvested on the trees when they are fully ripe. Farmers cut these pods with sharp long knives and collect the seeds from the pulp. One single pod’s pulp contains around 40 to 50 cocoa bean seeds. Once these cocoa beans are collected, they are fermented till the beans change from gray to brown to purple and develop their aroma. These cocoa beans are dried and collected in containers to be sent for cocoa processing and chocolate production sites in Europe, America, and Asia.

Cocoa beans to Cocoa Liquor

Cocoa beans are examined for quality and then cleansed from stones and dirt. Cocoa nibs are then obtained by removing the shells around cocoa beans. These nibs (the inside part of cocoa beans) are roasted cocoa beans to develop their aroma. The aromatic nibs are then put into a special grinder where they are grounded to a very fine liquid cocoa mass. This smooth liquid mass, although it doesn’t contain any alcohol, is known as Cocoa liquor.

Cocoa liquor to Cocoa butter & Cocoa Powder

Cocoa liquor is the purest form of chocolate and can be directly used in the manufacturing of different types of chocolates. However, cocoa liquor can be further processed into cocoa butter and cocoa powder.

Cocoa butter

Cocoa beans contain about 58 % cocoa butter, a natural fruit fat which is retained in cocoa liquor as well. Cocoa liquor is pressed to squeeze out the cocoa butter which is sold to chocolate makers, cosmetic companies and pharmaceuticals as it has many health benefits cocoa butter[4] has to offer- it’s a powerful source of antioxidants for the potential benefits of anti-aging, reducing hair loss and fighting inflammation among other various advantages.

Cocoa Powder

Image Source: https://www.santabarbarachocolate.com/rainforest-bulk-cocoa-powder/

Cocoa liquor when processed to separate cocoa butter (the white part of chocolate) from the cocoa solids (the brown part of the chocolate), leaves cocoa press cake (a heavy dark brown solid). This cocoa press cake is milled into cocoa powder. This is the remains of fermented, dried and roasted cocoa beans, pressed and then ground. This cocoa powder is the essence of the chocolate's flavor without any addition of sugar, fat or milk. It's a rich source of anti-oxidants and is commonly used in baking and brewing hot chocolates. There are actually two types of cocoa powder available in the market known as natural and Dutch-process cocoa powder.

Difference between Dutch Process & Natural Cocoa Powder

Natural cocoa powder is medium to light brown in color and is quite popular for making brownies, ice cream, cookies and chocolate cakes. Cocoa powder is naturally acidic and typically has a pH between 5 and 6. This gives cocoa powder sharp flavor with bitterness and astringency. It is often paired with baking powder in recipes as baking powder is alkaline in nature and that balances the acidity level in natural cocoa powder.

The Dutch process cocoa powder is not as common as natural cocoa powder and is found mostly in Europe. It is rich, deep and sometimes reddish to black in color. What makes it different from natural cocoa powder is that the cocoa beans are washed in a potassium solution to neutralize the acidity of pH 6. This process is the Dutch process and the cocoa powder is only marginally acidic with smoother and mellower flavors when treated this way.

While the natural cocoa powder is different from the Dutch process powder, it doesn’t necessary mean that one is better than the other. They can be used interchangeably depending on one’s preference for flavor and texture. Here is an interesting video [5] on the difference between natural and Dutch process cocoa powder if you want to know more about the differences.

Cocoa fruit to Chocolate

Cocoa liquor and cocoa butter are the key parts of chocolates making. Different varieties of chocolates can be made using different ingredients such as basic good dark chocolate, which is the combination of chocolate liquor, cocoa butter, and sugar. Milk chocolates has ingredients such as cocoa liquor, milk powder, sugar, and cocoa butter. White chocolate is a blend of cocoa butter, sugar, and milk powder. Vanilla and vanilla essence is added to enhance the flavor and to smooth flavors in all types of chocolates.

All ingredients are measured as per recipe and are blended into a homogeneous chocolate dough. The chocolate dough is then refined between rollers to form a fine chocolate mass smoothing out the texture and rounded sugar crystals. After this grinding and mixing of the chocolate dough, the chocolate is put into large tanks with big rollers called Conches.

Conching

The conching is known as the process in which all the ingredients of chocolate are thoroughly blended and mixed for a long period of time lasting from several hours to days depending on the chocolate type and how much sugar is in the recipe. The more time it takes to blend all ingredients, the more refined is the taste and texture of the chocolate. Blending of all flavors and textures can be done through this kneading process until the aromas are fully developed according to the chocolate maker's decided flavor profile. Conching is a necessary part of chocolate making process because:

- Any moisture left in the mixture is evaporated.

- The cocoa butter present in the cocoa liquor melts fully and spreads through all the tiny particles of chocolate.

- Volatile acid present in the mixture are partially or totally disappeared depending on the conching time.

- Depending on the heat and conching time, caramelization process takes place. This affects the flavor of the chocolate and this step is particularly important for white and milk chocolates.

Tempering & molding of chocolate

Once the conching is complete, the chocolate is ‘tempered' through a gradual decrease in temperature. During tempering, the chocolate is warmed and cooled repeatedly until it reaches the desired temperature that creates an even crystallization of the cocoa butter ingredients throughout the chocolate. Tempering is what gives the chocolate smooth texture and snap when broken into two pieces. As soon as the chocolate is properly tempered, it's now ready for additional inclusion of ingredients such as roasted almonds, hazelnuts or sea salt.

The chocolate is poured into mould where it forms the shape of a bar. It is cooled until it becomes solid and ready to be wrapped in an inner wrap designed to keep it fresh for 24 months. The chocolate bars are then packed, labeled and shipped.

Conclusion

So the next time you take a bite of Santa Barbara Chocolate you’ll know how the chocolate made it from the farm to you. While tasting imagine the far off lands you are journeying to through your palate.

References:

1- https://en.wikipedia.org/wiki/History_of_chocolate

2- https://www.statista.com/statistics/238849/global-chocolate-consumption/

3- https://www.worldcocoafoundation.org/blog/history-of-cocoa/

4- https://www.organicfacts.net/health-benefits/oils/cocoa-butter.html

5- https://www.youtube.com/watch?v=O5ewjyH2-NM&feature=youtu.be